How To Help Businesses

Is the on-site equipment compliant with safety regulations? Have vehicle equipment undergone safety inspections? The On-Site Machinery and Equipment Mobile Management System refers to safety management measures for hazardous machinery and equipment. These devices may pose potential risks and require strict control and supervision to ensure the safety of employees and others. Information system management can effectively assist contractors in the execution and supervision of on-site machinery and equipment.

Detect hazards and confirm safety.

Digital Record

Combine Contractor Access Management System

Reminders and Notifications

Statistics and Reporting

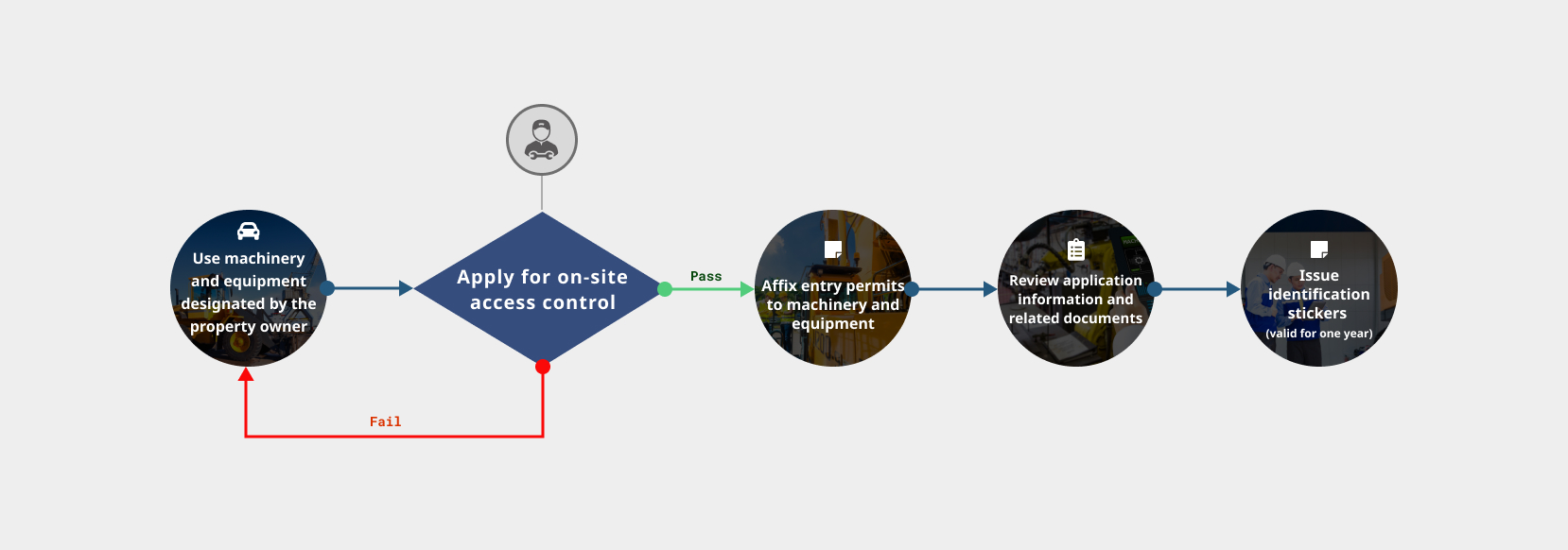

Flow Description

- Contractors using machinery and vehicles designated by the property owner must adhere to on-site access control, obtain permits, and display an "XX Factory Electrical Equipment Entry Permit" on the machinery or vehicles.

- Controlled equipment can be managed under different property owners, but compliance with regulations remains a top priority. For example, controlled electrical equipment includes welding machines, generators, distribution panel switches, pipe cutters, air compressors, and machinery announced by the factory. Entry of electrical equipment to the site must be applied for with the property owner's supervisory department and display an "XX Electrical Equipment Entry Permit" on the equipment itself.

- After checking the relevant application documents for electrical equipment, an identification sticker for the current year will be issued following the approval date, valid for one year.

- Immediate reporting and handling of abnormalities are required from operators.

- Vehicle applications are annual, with one application per year. When applying for vehicles, you can choose a yearly basis (conditions for the following year can only be selected in December).

Digital Record

Use a mobile information management system to create and manage digital records of contractor on-site machinery and equipment. This includes identification information, relevant documents, and training records. The information system allows convenient access and updates to this data, ensuring the completeness and accuracy of records.

Reminders and Notifications

The information system can send reminders and notifications, prompting relevant personnel to implement necessary safety measures. For instance, when hazardous machinery requires regular inspections or maintenance, the system can automatically notify appropriate individuals.

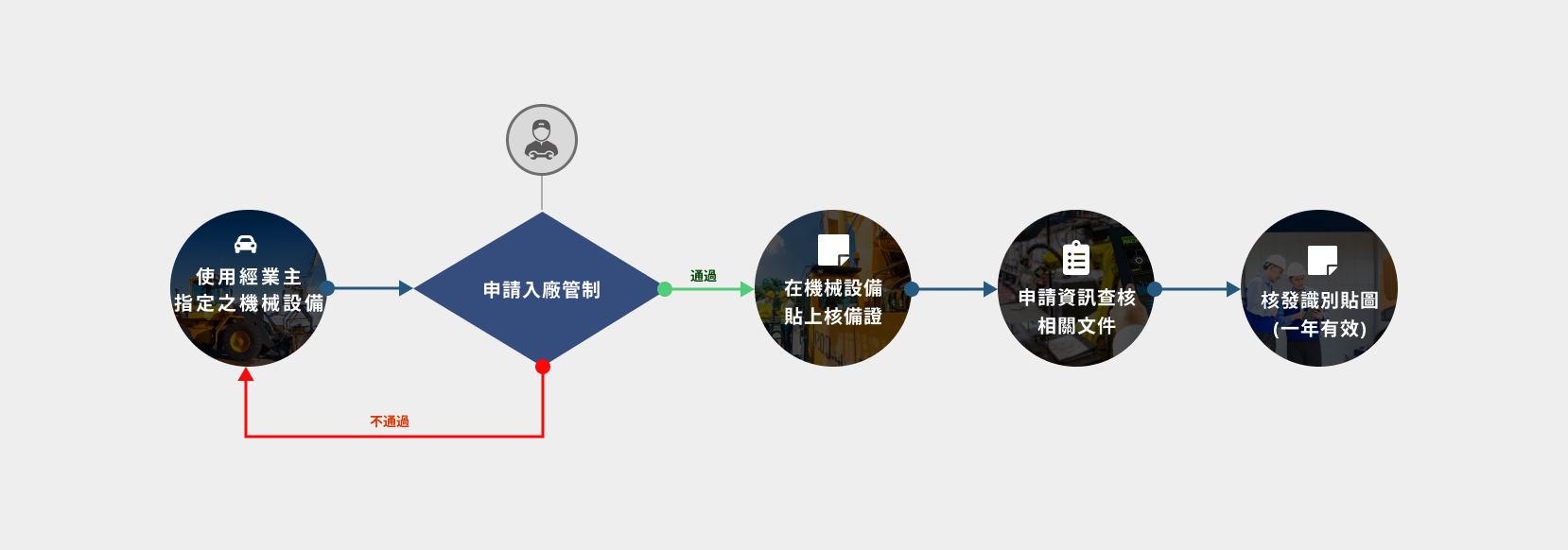

流程說明

- 承攬商入廠使用經業主指定之車輛機械,應接受業主入廠管制,經申請許可始得入廠,並在車輛機械貼上「XX廠區電氣機具進廠核備證」。

- 可納入管制的設備可依照不同業主管理納入,但仍是要以法規規範的為首要。例如管制的電氣機具含電焊機、發電機、配電盤開關箱、切管機、空壓機及廠方公告之機具。電氣機具進廠(場)必須向業主監造部門申請核備,並在電氣機具本體上貼「XX電氣機具進廠核備證」。

- 依據電氣機具設備申請資訊查核相關申請文件後,給於核準日期後核發該年度通行識別貼圖,一年有效。

- 需要即時通報、即時處理異常的業者。

- 移動車輛是採年度的申請,每年度申請一次。申請車輛時可以選擇年度(12月份才可選下年度的條件)。